POWERFUL TOOL FOR ELECTRONICS, PRINTING, COATING AND ADHESION

- This surface treatment device is suited for PE, PP, POM, various plastics, metals and troublesome adhesive materials.

- Suited for injection molding or extruding products. Can be installed on a production line or for individual parts treatment.

- Easily matched to the production line speed, required treatment width, product material and configuration.

- Simple and compact construction.

- The unit employs low frequency, high voltage discharge principle for extremely fast surface treatment.

- Choice of one to four discharge heads effective width 35 mm.

- The surface treatment can greatly improve adhesion capability on plastic product surfaces, ensuring excellent laminating, printing, and painting effects.

- Universal mounting brackets are optional.

- A proximity sensor is available to cycle the discharge on and off when parts approach and leave the treatment station.

FIRST with Multi-Surface Corona Treating for 3-Dimensional Products!

For improved bonding of inks, adhesives and coatings, Plasma-Jet TM treats plastic and metal products with greater application flexibility, surface coverage and speed.

Operating Principle:

Corona treatment with a Plasma-Jet system uses an electrical discharge (corona) to selectively increase the surface wettability of plastic and metal products. One to four discharge heads are positioned for complete coverage of the desired surfaces prior to application of labels, nomenclature or graphics.

Application Assistance:

To evaluate your application characteristics and treatment requirements, Corotec maintains a complete testing facility and can also arrange an on-site demonstration at your facility. Working with your actual products, we will recommend a specific Plasma-Jet system, including the number of discharge heads and their placement for optimum results.

Better Than Open Flames:

Compared to old-style flame treatment, Plasma-Jet systems provide modern technology to help meet today strict safety and health standards, insurance regulations and productivity requirements.

Safer Operation:

Corona systems eliminate the danger of burning and heat-distorting products and processing equipment.

Higher Consistency:

Corona treatment results are predictable and consistent, unlike flame systems that require precise adjustment of air/gas mixtures.

Easier Installation:

The Plasma-Jet unit plugs into an ordinary 120V outlet; no gas lines or other utilities are required.

Better Working Environment:

Corona treatment does not subject employees to the hazardous gases, open flames, combustion by products and heat generation of flame treatment.

It is suitable for PE, PP, POM, various plastics, metals and troublesome adhesive materials.

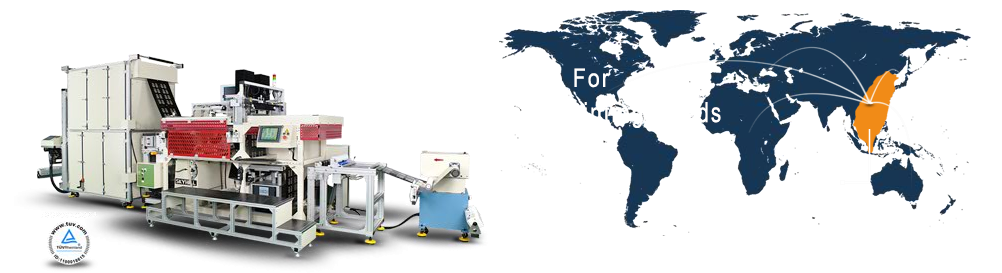

Ming Tai advances its surface treating technology with new generation Plasma-Jet corona treating systems for three-dimensional products. Now you can treat multiple surfaces and difficult configurations with superior one-pass coverage, consistency and convenience. Capable of handling high line speeds and complex part geometries, Plasma-Jet systems solve surface adhesion problems for a wide variety of products and applications:

* Caps and closures

* Painting, decorating

* Cups and containers

* Consumer products

* Extruded pipe, tubing, profiles

* Medical and health care products

* Electrical/electronic components

* Direct printing

* Hot stamping

* Pad printing

* Adhesive coating

* Adhesive bonding

* Wire and cable

* Laminating

No deformation after treatment

*The Plasma Jet corona discharge generates very little heat, which allows surface treating of sensitive materials such as light films without distortion.

*Plasma-Jet corona treatment eliminates the inefficiencies, safety hazards and product damage potential of open flame treatment, chemical surface preparation and sanding techniques, while offering improved bonding results as well

*Application Flexibility

Simple and compact, Plasma-Jet systems can be sized and configured to suit your production environment. They are easily matched to your line speed, required treatment width, product material and configuration. The Plasma-Jet power unit is portable and can be moved wherever needed or permanently mounted in a convenient location. The discharge heads (one to four, depending on model selected) can be extended up to 10 feet or more away from the power unit. Optional universal mounting brackets, available from Ming Tai, may be used to hold the discharge heads at the right angle and position on your production line, and are especially handy when your treatment applications change frequently. A proximity sensor can also be added to cycle the corona discharge on and off as parts approach and leave the treatment station.